How to Decide on the Right Method

Which shrink wrap packaging method you choose will depend on a number of factors, such as the type of product to be wrapped, and the main purpose of the shrink wrap. You need to consider:

* Presentation and appearance

* Protection during transport and storage

* As an alternative to cartons and boxes

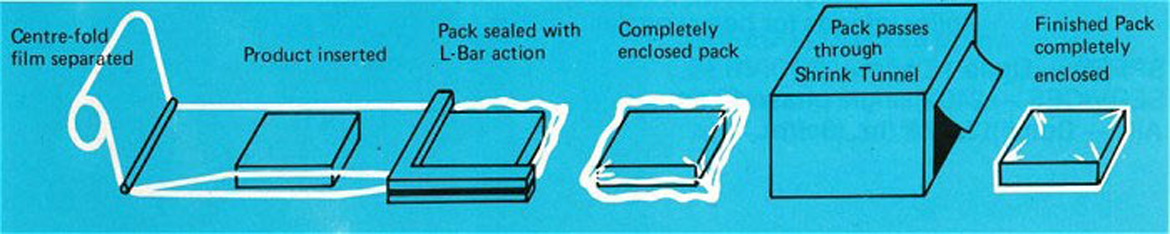

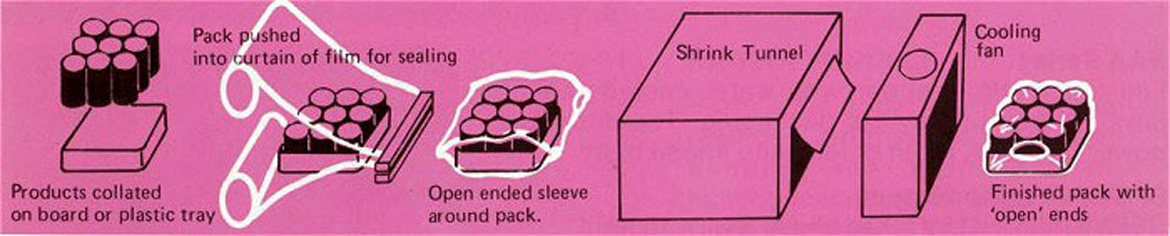

Shrink wrap packaging is typically done with an L-Bar sealing machine or a Sleeve wrapping machine (also referred to as a Bundle wrapping machine). These two packaging methods are illustrated in the following diagram.

This method uses center-folded shrink film. This is where one side of the film is open while the opposite side is folded to form a U-shaped envelope.

The product is inserted into the U-shape between the top and bottom layers of film and the L-shaped sealing bar welds the film closed around the product.

The L-Bar sealing system results in a completely enclosed pack which then passes through a hot air shrink tunnel to shrink the film tightly around the product.

Sleeve wrapping

This method uses two rolls of flat film, usually mounted above and below the product, which are welded together by a straight sealing bar to form a web through which the product is pushed. This results in an open-ended sleeve being formed around the product.

After passing through a shrink tunnel, the film shrinks around the product leaving the pack with open ends (sometimes referred to as bulls-eye ends).

Practical Applications

These two wrapping systems lend themselves to a huge variety of shrink packaging applications.

Completely enclosed shrink packs (produced on L-Bar sealing machines) are often used in retailing, where product presentation, appearance and tamper evidence is of utmost importance. Typical applications include:

- Confectionery and chocolate boxes,

- Stationary products including greeting cards, reams of paper and diaries

- CD sleeves and computer disks

- Cosmetic and make-up cartons, shampoo bottles and hair-spray

- Kitchen flat packs, lacquered doors, timber moldings and hardware products

Open ended shrink packs (produced by Sleeve wrapping machines) are most commonly used in distribution and warehousing where products are packed in bulk and a cheap alternative to cartons provides savings and economy. Sleeve wrap can be applied around bulk trays of product or free-standing, collated product in 6, 12 or 18 pack configurations. Applications include:

- Bottled water and beverages in bulk packs or on trays

- Processed products like flour, sugar and rice packs

- Ice-cream tubs for bulk distribution

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: