What do you need to consider when selecting retail packaging

Cost, product type and brand.

The supermarket isle is the retail battleground. What gives your product an edge over the competition?

Retail packaging is one of the biggest influences at the final point of sale. When packed in between competing products, packaging starts an invisible conversation with the customer. A customer’s decision can be influenced by the product’s quality, appearance and cost. Ask yourself: “What conversation is packaging having with my customers?”

Of course, good packaging also needs to balance these considerations with a practical purpose. Retail packaging should be able to protect the contents from damage and contamination, and warn the consumer when the product has been tampered with.

Flashy or functional; whatever your budget, product or branding considerations, ITT Jetpak have your business’ ideal packaging solution. For advice on materials or machines, call the ITT Jetpak team on .

Cost Considerations

As part of any business investment decision, one of the key considerations is cost. How much you can spend on packaging is dependent on the intersection of your budget, the requirements of the product and the overall branding strategy. Flashy and colourful packaging may look the most appealing, but it may not be the best fit for your product or budget.

When considering how much to invest into packaging, consider not just the cost of materials, but the required overhead for machinery and production-line upgrades. Each method of packaging employs a different type of packaging technology and associated materials. Making the right investment decision requires weighing up the advantages of each method with their associated cost.

Product Requirements

Another key factor is the product’s packaging requirements. Is the packaging purely visual? Does it protect it from damage or contamination? What are the labelling requirements?

This consideration comes down to the type of product to be packed.

- Food and beverage containers will need to protect the product from damage and contamination.

- Generic household items, such as cleaning products, will have a great priority on branding and labelling.

- Luxury items, such as cosmetics, will need highly visual and appealing packaging.

- Pharmaceutical and health products will need to have tamper evident packets and be clearly labelled.

Branding Strategy

Last but not least, the packaging needs to reflect your products overall branding strategy. When your product is sitting on a retailer’s shelf, how does it stand out from the crowd? Why would a consumer pick your product over the one right next to it, or above it, or below it? Your packaging should reflect your brands’ overall message.

In a branding sense, packaging can employ both tactile and visual cues by determining a product’s appearance, texture and shape. If a product is aimed at a premium or luxury market, these factors become more important at the retail point of sale.

Finding the Best Retail Packaging Solution

When you have taken all cost, product type and branding requirements into account, you can select the best retail packaging machinery and material to suit your product.

Retail Packaging Machines

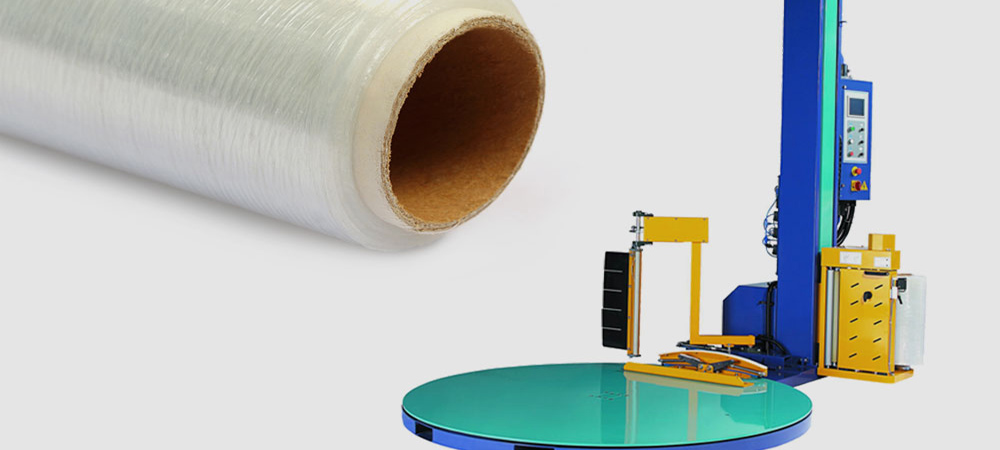

- Shrink Wrap Systems. These versatile machines come in a range of configurations to suit all kinds of products and budgets.

- Shrink Sleeve Applicators. These machines are ideal for wrapping items into bundled configurations for both retail display and distribution.

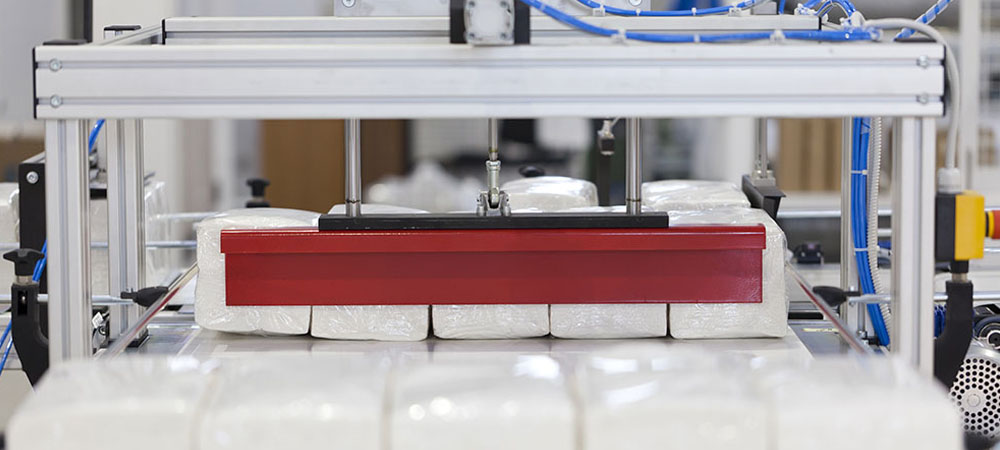

- Horizontal Flow Wrappers. These machines are highly efficient packing machines, with packing speeds of between 20 – 800 individual pieces per minute, depending on application and model.

Retail Packaging Materials

- Polyolefin Films (POF). This type of high quality film is used in shrink wrap applications. Shrink wrapping is an easy and cost effective way to wrap a variety of products.

- PVC Films. This type of film is often used in shrink sleeve applications. Shrink sleeves are an economical and versatile alternative to costly label printing and application.

- Bi-axially Orientated Polypropylene (BOPP). This type of film is commonly used for Horizontal Flow Wrappers. This packaging method is a high speed and highly efficient way to pack individual items, such as food, confectionery and bakery products. They are also commonly used for wrapping wipes, sponges, soap and tableware, including disposable cutlery and paper napkins.

We Can Help. We’re Retail Packaging Experts.

At a loss trying to find the best retail packaging for your business? We can help.

ITT Jetpak is one of the leaders in providing retailers, suppliers and manufacturers with efficient, cost effective packaging solutions. We can supply new and used machines, as well as quality materials suitable for printing and branding.

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: