Improve efficiency and reduce your costs.

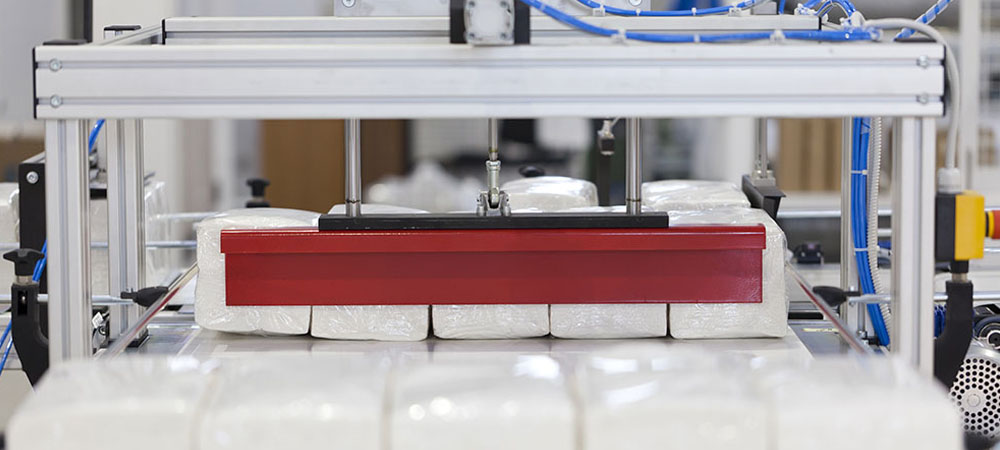

When it comes to pallet wrapping machines, there are several ways that they can directly improve improve your efficiency, reduce your costs, and boost your bottom line.

One of the advantages of using a pallet wrapping machine is that they can stretch pallet wrapping film much further than a human can.

Pallet wrapping machines can stretch film by up to 300%, depending on the model and settings, while manually stretching typically only yields a 50% stretch.

Having the ability to stretch your pallet wrapping film six times more will provide significant savings to your materials expenditure.

Not only that, but machine wrapping will eliminate the inconsistencies of manual wrappings so you will know exactly how many pallets you can wrap with a roll of film, allowing you to plan your ordering more effectively.

Wrapping a pallet is usually the last task before your goods move on to the next stage of your production.

Depending on how your business is set up, a delay in moving your goods to the next step, whether that’s delivery, storage, or something else, could cause other delays to flow on from this.

If you have a delivery driver sitting around waiting, then getting pallets wrapped quickly could be critically important to your production.

Machines can wrap pallets in roughly half the time that humans can, and they ensure a consistent result.

This will minimise worker downtime since you won’t have dependent tasks waiting for the pallets to be wrapped and workers can move on to other tasks instead of wrapping pallets manually.

Pallet wrapping machines usually cost less than one year of wages for a part-time employee. The time saved by a pallet wrapper will allow your employees to do other tasks when they would have been wrapping pallets manually.

This means that purchasing a pallet wrapper could be more efficient for your business than hiring a new employee.

Ensuring that your production is efficient from the beginning will also set your business up for steady and sustainable growth in the future.

Pallet wrapping machines allow you to save on employee wages and may not cost as much as you think

If the wrapping film is not tight enough from the manual wrapping, your goods can shift and break while being transported.

The cost of replacements or the loss of customers could have a big impact on your bottom line. Pallet wrapping machines ensure that every pallet is wrapped perfectly so that your stock is not at risk of breakage.

Other benefits of pallet wrappers

There are many other benefits of pallet wrapping machines that may have an indirect effect on your bottom line. Some of these include:

- Reduced OHS risks – Manually wrapping a pallet is very labour intensive, and it can be the cause of worker injuries, especially to the back.

- Professional look – Because pallet wrappers always produce the same high-quality result, your products will always look professional to your customers.

- Customisable features – There are many different options and settings that allow you to customise your pallet wrapper so that it perfectly suits the needs of your business.

Get expert advice on the best machine for your business

The team at ITT Jetpak are experts in the packing industry. Our specialists will be able to explain your options and advise you on the machines that best suit the needs and budget of your business.

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: