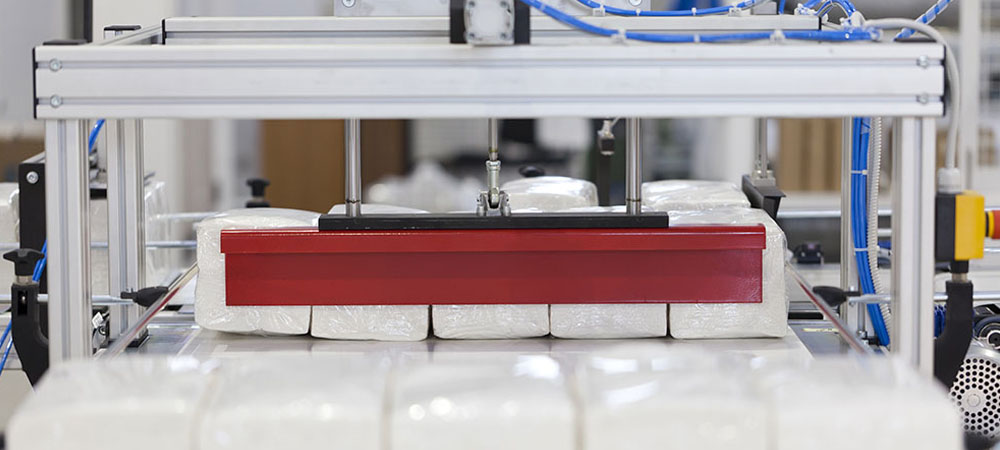

Guide to keeping your pallet wrapping machine in good working order

Since pallet wrapping machines are an investment in efficiency for your company, it’s important to protect that investment with regular maintenance. In some ways, a pallet wrapper is like a car: regular servicing and maintenance is the best way to ensure that your machine has the longest lifespan possible with the fewest breakdowns.

To ensure that your pallet wrapper doesn’t break down, you should treat it like you’d treat your car. A scheduled maintenance program will reduce the likelihood of a failure that will interrupt your work and cause downtime. This will end up saving you money by preventing breakdowns and interruptions to production as well as more costly repairs.

The frequency of maintenance and the amount of time it will take will vary depending on the type of machine that you have and how heavy your usage of it is. Semi-automatic and automatic pallet wrappers have additional mechanisms and may take longer to service than manual machines.

An ITT Jetpak mobile technician will be able to provide pallet wrapping machine servicing by inspecting the machine and reporting any suspected wear and tear. They carry a wide range of spare parts and will address any issues before they have a chance to cause a breakdown in the future.

There are also steps you can take to help prevent wear and tear to your pallet wrapper. Along with regular maintenance, these tips can help you save time and money down the track.

- Prevent rubbish from accumulating around the machine – Rubbish getting under the turntable can cause the turntable belt to break or jam.

- Keep the machine in a dust-free environment – This may not always be possible, but ideally the machine should be kept away from any other equipment that produces dust.

- Prevent exposure to anything that may cause damage – Keep the machine well away from the elements or any other substances that may cause wear and tear.

Need a new pallet wrapping machine?

Generally speaking, semi-automatic and fully automatics pallet wrappers are for higher volume use while rotary ring arm style pallet wrappers are for top end speed. It’s also worth considering a pre-stretch model since these stretch pallet wrapping film further, saving you money in the long run.

For more information about pallet wrapping machine options, review our pallet machine price guide.

ITT Jetpak is an industry leader in packaging machinery. We offer comprehensive packaging solutions for our clients, including:

- Prevent rubbish from accumulating around the machine – Rubbish getting under the turntable can cause the turntable belt to break or jam.

- Keep the machine in a dust-free environment – This may not always be possible, but ideally the machine should be kept away from any other equipment that produces dust.

- Prevent exposure to anything that may cause damage – Keep the machine well away from the elements or any other substances that may cause wear and tear.

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: