Our guide to choosing the best pallets for your business

It is quite likely that standard wooden pallets will meet all the needs of your business. However, there are other pallet options that are worth considering that provide different pros and cons that may be more important to your business.

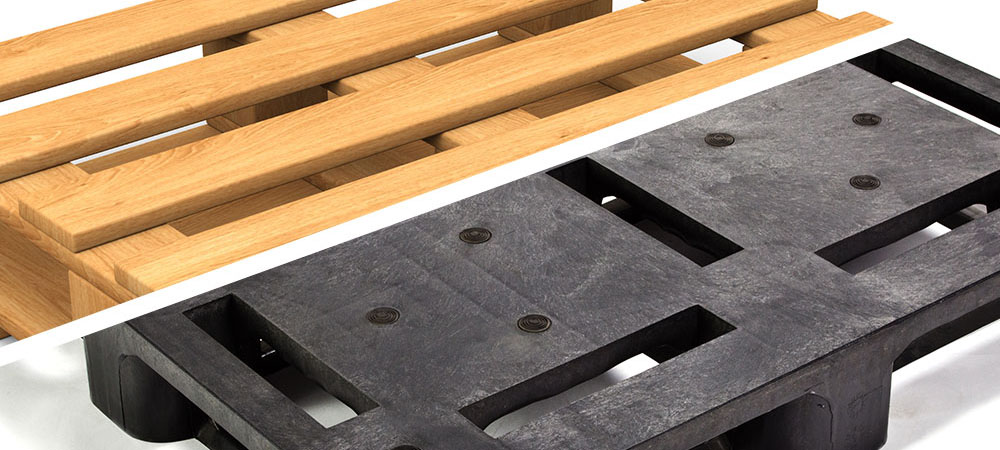

The best pallets to use: wooden vs. plastic

This comparison will look at the two most common pallet choices, wooden and plastic. Neither option will be the best pallet to use in every situation, for every business.

The right investment decision can be made by weighing the pros and cons of each pallet type against the needs of your business.

| PROS | CONS |

|

|

| PROS | CONS |

|

|

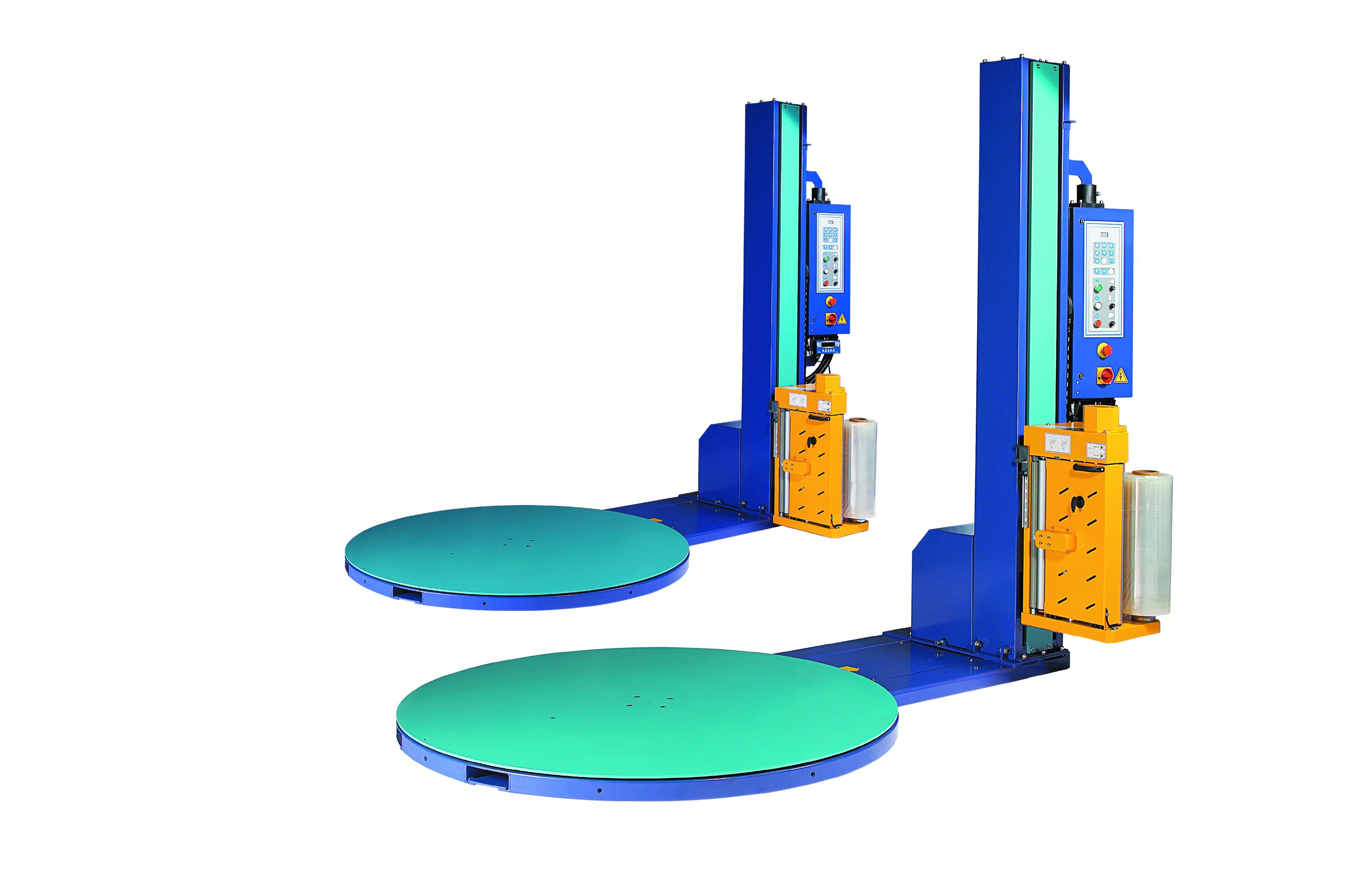

There are also steps you can take that to help prevent your pallet wrapping machine from getting damaged.

We offer our customers:

- Dedicated mobile technicians for machinery maintenance and repairs

- A 12-month warranty on new pallet wrapping machines

- A wide range of packaging materials

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: