And what is pallet wrap used for?

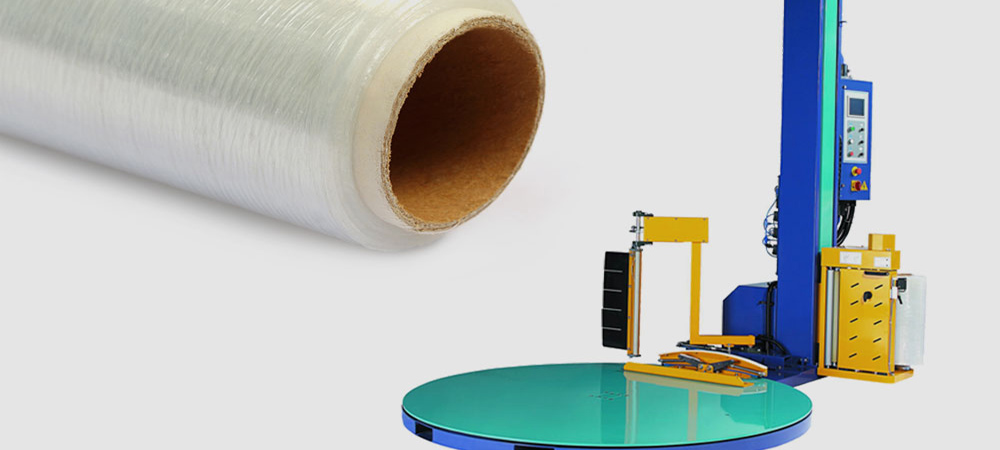

Pallet wrap is exactly what it sounds like – a type of plastic film that can be stretched, either by hand or wrapping machine, around a pallet.

While it is most often used to secure goods for transportation, pallet wrap has many other uses; it can be used in horizontal spiral wrapping machines to bundle or protect a range of goods and freight items. This technique is widely used for aluminium extrusions and timber moulding to wrap and bundle together. It’s also a popular method of bundling flat pack cabinets in the kitchen industry.

Pallet wrap is often referred to by a range of different names – including ‘stretch film’ and ‘stretch wrap’ etc. However, there is actually a difference between pallet wrap and other similar films.

Specifically, it’s the ability for pallet shrink wrap to stretch and then pull back in – similar to a rubber band – that sets it apart. This particular trait is one that most other types of plastic wrapping lacks.

The answer to this question depends entirely on what you are trying to wrap. In general however, the more you can stretch the film, the tighter the wrap will be. A pallet wrap that stretches well ensures the wrapped load is tightly secured to the pallet, reducing the chance of breakages and other damage to your goods in transit.

So when selecting wrapping materials, it’s smart to choose a supplier with a wide range of pallet wrap films. This way, you can choose a higher-end film for a tighter fit for your goods. Or if you’re wrapping goods but not transporting them, you can select a lower-cost option that better fits your budget.

Most suppliers will only stock a single film and try to apply it to most machines. At ITT Jetpak however, we are able to supply a specific material for each machine which in turn will reduce costs. For example, our hand-stretch films are designed to be easy to use and cost-effective – reducing the amount of film used per pallet.

The answer to this question depends entirely on what you are trying to wrap. In general however, the more you can stretch the film, the tighter the wrap will be. A pallet wrap that stretches well ensures the wrapped load is tightly secured to the pallet, reducing the chance of breakages and other damage to your goods in transit.

So when selecting wrapping materials, it’s smart to choose a supplier with a wide range of pallet wrap films. This way, you can choose a higher-end film for a tighter fit for your goods. Or if you’re wrapping goods but not transporting them, you can select a lower-cost option that better fits your budget.

Most suppliers will only stock a single film and try to apply it to most machines. At ITT Jetpak however, we are able to supply a specific material for each machine which in turn will reduce costs. For example, our hand-stretch films are designed to be easy to use and cost-effective – reducing the amount of film used per pallet.

What’s the difference between pallet wrap and pallet shrink wrap?

Using the proper materials for your pallet wrapping job is just one important factor in achieving the results you want. The other thing to ensure you get right is your choice of wrapping machine – and ensuring that machine is of a sufficient standard.

For more information or to place an order, We’re here to help, check out our tutorials, machinery examples, best practices or simply call us for more information: